For growing food and beverage brands, choosing the right glass jar manufacturer and developing the right custom glass bottles is a strategic decision. Packaging affects product safety, brand positioning, logistics cost and even how retailers and consumers perceive your products.

By working with a reliable glass jar manufacturer in China, purchasing managers, importers and brand owners can combine quality, design flexibility and competitive pricing within a single packaging partner.

This guide is written for B2B buyers and brand owners. You will learn:

- Why the choice of glass jar manufacturer is critical for your brand

- How glass jars and custom glass bottles support product safety and compliance

- When stock jars are enough and when custom glass bottles add real value

- How to match packaging types to different product categories

- How to evaluate and cooperate with a China glass jar manufacturer

Why the Right Glass Jar Manufacturer Matters

The right glass jar manufacturer is more than a container supplier. A good partner helps you:

- Protect product quality from filling to end of shelf life

- Meet food-contact regulations in your target markets

- Optimize packaging cost and logistics efficiency

- Launch new SKUs faster, using both stock jars and custom glass bottles

- Build a consistent brand image across different product lines

Involving your manufacturer early in the development process allows you to design jars and bottles that work for both marketing and production, instead of making packaging decisions at the last minute.

Performance & Compliance Benefits of Glass Jars and Bottles

Product safety and material neutrality

Glass is non-reactive and non-porous. It will not leach into food and does not absorb oils, colors or aromas. When you work with a professional glass jar manufacturer, glass formulations are developed specifically for food-contact applications, reducing risk for your quality team.

Shelf life and flavor protection

In combination with well-designed closures, glass jars and custom glass bottles form an effective barrier against oxygen and moisture. This is essential for categories like spices, sauces, coffee, jams and honey. A capable manufacturer will match jar geometry, neck finish and cap to help you hit your shelf life targets.

Premium brand perception

Glass packaging is associated with natural ingredients and higher quality. For brand owners, investing in distinctive custom glass bottles reinforces a premium image and supports better shelf impact in both offline and online channels.

Compliance and market access

Experienced glass jar manufacturers are familiar with market regulations and can support documentation and testing where needed. This helps reduce risk when you launch into new regions or work with large retail chains.

Custom Glass Bottles vs. Stock Jars: How to Decide

When stock jars are the best choice

Stock jars from a glass jar manufacturer are pre-designed items produced with existing molds. They are ideal when you:

- Need fast time-to-market for a new SKU

- Are testing a new product or category

- Have limited or uncertain volumes

- Want to minimize upfront investment

For many private label and entry-level brands, stock jars provide a practical, low-risk starting point.

When custom glass bottles add strategic value

Custom glass bottles become attractive when you want to differentiate your brand and secure a strong shelf identity. With a structured custom glass bottles program, you can:

- Create unique silhouettes that are hard to copy

- Integrate embossed logos or design elements into the glass

- Optimize bottle geometry for your filling and labelling lines

- Specify glass color, weight and base design to support your brand story

Custom solutions typically require higher MOQs and initial tooling costs, but they support long-term brand building and often justify premium pricing.

A hybrid approach with your glass jar manufacturer

Many brands follow a hybrid path: use stock jars during the testing and early growth phase, then migrate core SKUs to custom glass bottles once demand is stable. Working with one manufacturer that offers both stock and custom solutions makes this transition smoother.

Matching Jar Types and Custom Glass Bottles to Your Product Line

A professional glass jar manufacturer will usually recommend different packaging families for each category. Below are typical examples.

Spices, herbs and seasonings

Spices and herbs require compact, controlled dispensing and strong aroma retention. Dedicated spice glass jars provide:

- Small capacities (30–120 ml) for efficient shelf space

- Standard neck finishes for shakers, grinders and flip-top caps

- Clear glass for easy identification and branding

Jam, honey and sweet spreads

Jam and honey usually carry a “natural” or “giftable” positioning. A dedicated jam and honey glass jar range often includes:

- Round, hexagonal or vintage shapes suitable for gifting and retail

- Stronger walls and reliable twist-off metal lids

- Multiple volumes for samplers, standard and family sizes

For premium ranges or seasonal collections, many brands upgrade these designs into custom glass bottles or jars with special embossing.

Coffee, tea and RTD beverages

Coffee and tea benefit from glass packaging because of aroma protection and premium perception. For ready-to-drink beverages like cold brew or coffee drinks, bottle-style containers are common. A coffee glass bottle range from a glass jar manufacturer typically offers:

- Round or square bottles compatible with standard bottling lines

- Neck finishes suitable for screw caps or crown caps

- Surfaces optimized for labels, sleeves or direct printing

Sauces, condiments and savory spreads

Sauces and condiments need containers that balance consumer convenience with filling-line efficiency. Wide-mouth jars make it easier to fill and empty thicker products, while narrower-neck bottles are well suited to pourable sauces. Standardizing neck sizes across these products with one glass jar manufacturer helps reduce closure and inventory complexity.

How to Work with a China Glass Jar Manufacturer

China is a major sourcing base for glass packaging. A reliable China glass jar manufacturer can offer large-scale production plus flexible service for both stock jars and custom glass bottles.

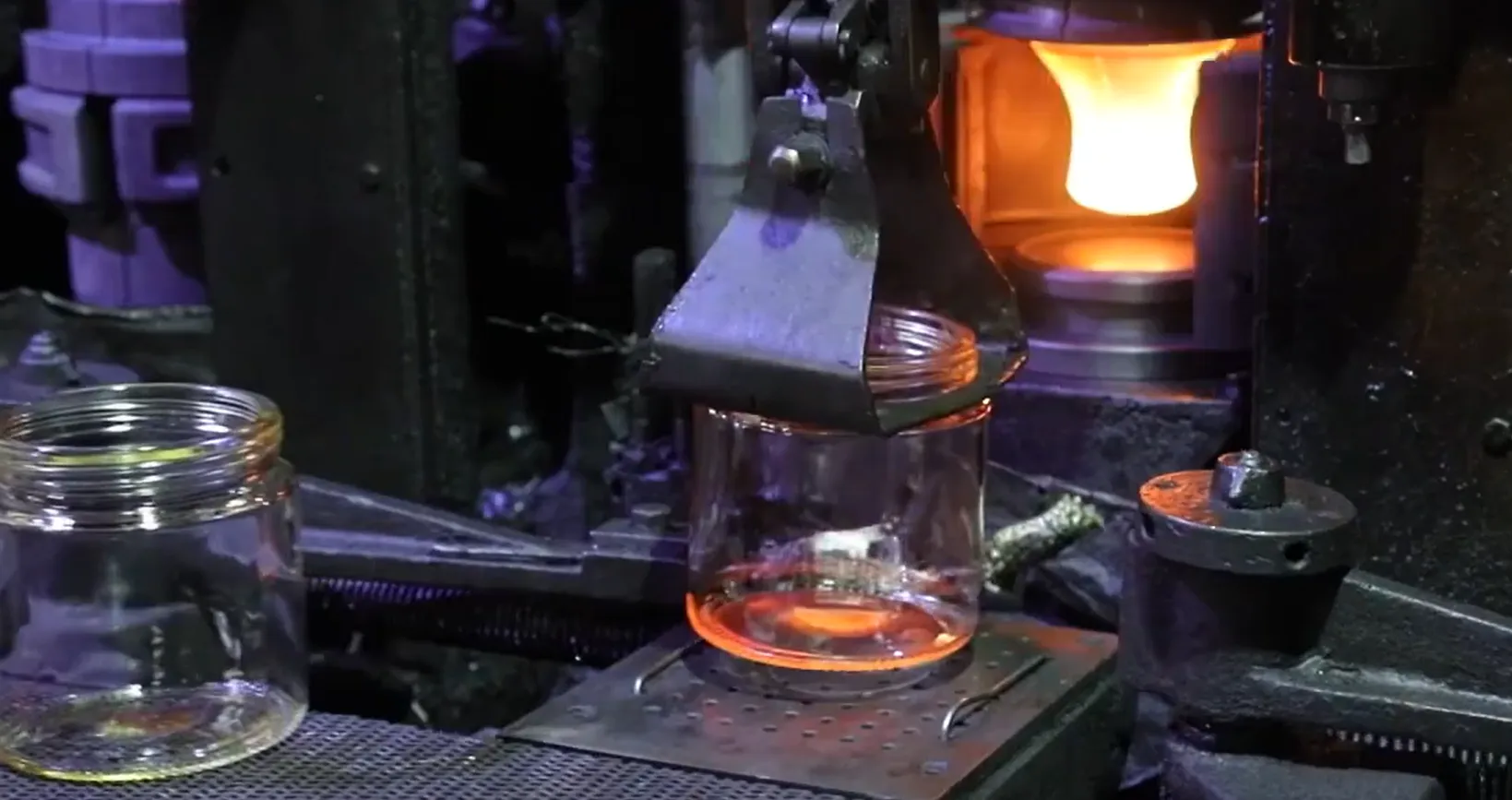

Production capability and quality control

- Stable glass formulations for food-contact applications

- Dimensional control for jar bodies and neck finishes

- Inspection for bubbles, stones, cracks and surface defects

- Export-ready packing (cartons, dividers, pallets) for long-distance transport

Range depth and modular design

A mature manufacturer maintains a wide catalog of jars and custom glass bottles for food, beverages and other categories. This allows you to:

- Cover many SKUs with stock molds

- Share neck sizes and caps across multiple products

- Scale into custom designs without changing suppliers

Decoration and closure integration

Beyond the glass, a full-service glass jar manufacturer can coordinate:

- Closures: metal caps, plastic caps, shakers, grinders, pumps, droppers

- Decoration: coating, frosting, printing, decals, sleeves, labels

- Packaging engineering tailored to your logistics routes

This integrated approach simplifies sourcing and reduces project management workload on your side.

From Idea to Custom Glass Bottles on Shelf: A Simple Process

When you decide to invest in custom glass bottles, a structured process with your manufacturer keeps the project under control.

- Define requirements – Product type, fill volume, markets, filling method (hot-fill or cold-fill), closure type, decoration needs and brand goals.

- Concept and technical drawing – The glass jar manufacturer translates requirements into bottle and jar shapes, including dimensions and neck finishes.

- Mold development – Once the design is approved, production molds for your custom glass bottles and jars are created.

- Pilot production and testing – Samples are produced for line tests, stacking tests, transport simulation and regulatory checks if needed.

- Mass production – After approval, the manufacturer schedules full production and coordinates closures and decoration.

- Logistics and replenishment – Packing is optimized for shipping, and replenishment plans are aligned with your sales forecast.

FAQ for Buyers Working with a Glass Jar Manufacturer

Q1. What information should I prepare before requesting a quote?

To receive accurate quotations from a glass jar manufacturer, prepare:

- Product category (spices, jam, honey, coffee, sauces, beverages, etc.)

- Target volume (ml) and estimated annual quantity per SKU

- Preference for stock jars or custom glass bottles

- Closure type (metal cap, plastic cap, shaker, pump, etc.)

- Decoration requirements (printing, labels, sleeves, coating, etc.)

- Target markets and any specific compliance standards

Q2. What are typical MOQs for stock jars vs. custom glass bottles?

Stock jars usually come with lower MOQs and are ideal for new or smaller projects. Custom glass bottles have higher MOQs because they require dedicated molds and setup. A good China glass jar manufacturer will propose realistic MOQs and can phase volumes as your brand grows.

Q3. How long does it take to develop custom glass bottles?

Lead time depends on project complexity, but the typical flow includes design, tooling, pilot production and mass production. Starting discussions early with your glass jar manufacturer helps align packaging development with your launch schedule.

Q4. Can one supplier handle both jars and custom glass bottles?

Yes. Many glass jar manufacturers in China offer both standard jars and custom glass bottles for beverages and sauces. This simplifies supplier management and helps you standardize quality and logistics.

Conclusion: Build Long-Term Value with the Right Glass Jar Manufacturer and Custom Glass Bottles

For serious food and beverage brands, glass jars and custom glass bottles are strategic assets. They protect product quality, support compliance, and create strong shelf impact in both offline and online channels.

By partnering with an experienced glass jar manufacturer, using stock jars where it makes sense and investing in custom glass bottles for your core SKUs, you can build a scalable packaging system that grows together with your brand.