Bottle Manufacturing

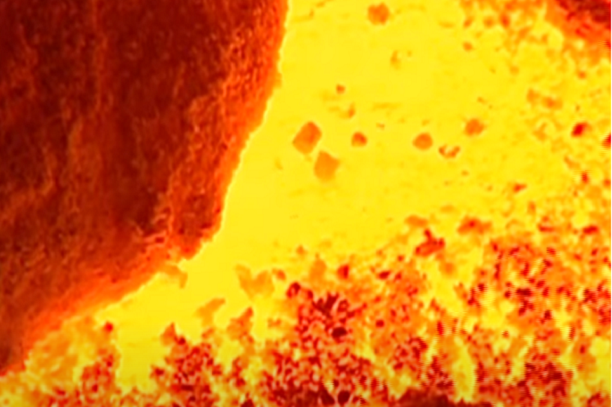

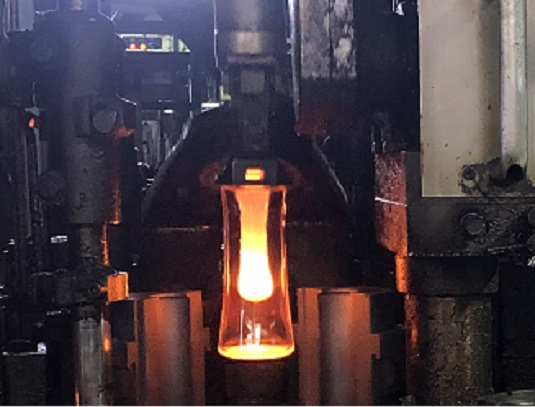

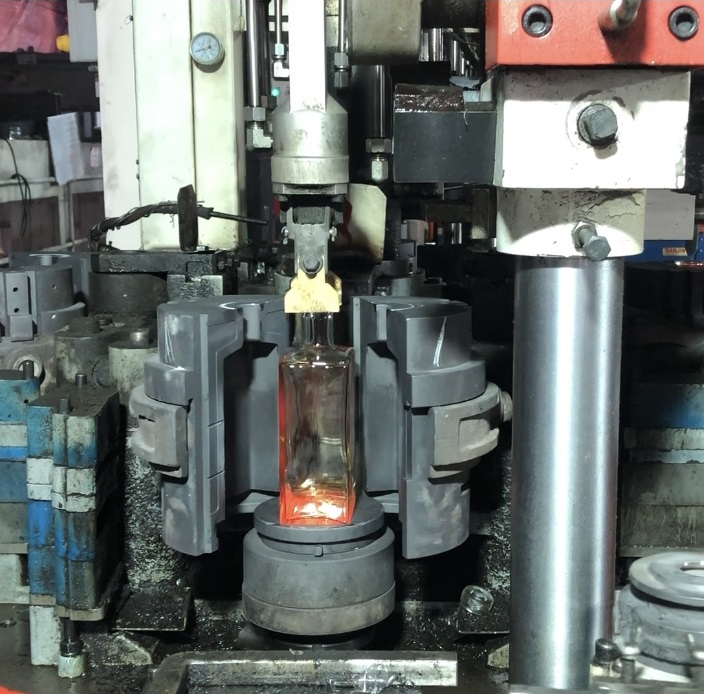

Glass bottle factory from natural ingredients through MC Glass bottle making process, we take shape glass packaging using advanced equipments, expertise and high quality standard to streamline manufacturing process and save the real costs