Glass Bottle Manufacturer for Custom & Wholesale Bottles and Jars

MC Glass is a factory-direct glass bottle manufacturer in China, supplying custom and wholesale glass bottles and jars for beverage, spirits, food, cosmetics, and pharmaceutical packaging. With stable capacity, in-house QC, and export-ready packing, we help global buyers scale repeat orders with lower sourcing risk.

Glass Bottle Manufacturer With Scalable Production Capacity

Factory-direct glass bottle manufacturer in China with stable capacity for repeat wholesale & custom orders.

Custom glass bottles

Design and supply custom glass bottles for liquor, spirits, perfume, water, oil, food and beverage packaging. Share a sketch or reference bottle—our team supports mold development, decoration, and export-ready packaging.

Bottle Manufacturing

See how our glass bottles are made—from raw materials to forming, annealing and inspection.

Learn how we control weight, thickness and finish dimensions for consistent quality and reliable lead times.

Work with a factory-direct glass packaging partner for custom molds, decoration, and stable wholesale supply.

Explore our capacity, QC standards, and export-ready packaging for safer global shipping.

Custom Glass Bottle Manufacturer for Brand Packaging

MC Glass is a factory-direct glass bottle manufacturer in China with 20+ years in glass packaging. We support custom bottle development for spirits, beverage, perfume and pharmaceutical brands.

What you can customize:

• Bottle shape & capacity (stock + custom molds)

• Neck finish & closure matching for your filling line

• Frosting, screen printing, decals, embossing & coating

• Export-ready packing for repeat orders

Custom Glass Jar Manufacturer for Food & Beverage Packaging

We manufacture and supply custom and wholesale glass jars for honey, spice, food and beverage packaging. Share your target size, lid type and quantity—we’ll reply with MOQ, lead time and packing suggestions.

Common options:

• Jar shape & capacity selection

• Closure matching (twist-off / lug caps / custom lids)

• Decoration for shelf impact (printing, decal, embossing, frosting)

• Export packing to reduce breakage

Glass Bottle Categories We Manufacture

Browse our main glass bottle categories for wholesale and custom orders—click to view sizes, closures, and decoration options.

End-to-End Project Management by a China Glass Bottle Manufacturer

We manage custom glass packaging projects with a clear delivery workflow—so you work with one accountable factory team from approval to shipment.

How we control repeat orders:

• Sample approval & spec confirmation (drawing, capacity, neck finish)

• Decoration consistency (frosting, screen printing, coating)

• In-house QC for neck finish, sealing fit, and appearance

• Export packing to reduce breakage (carton partitions, palletizing, loading checks)

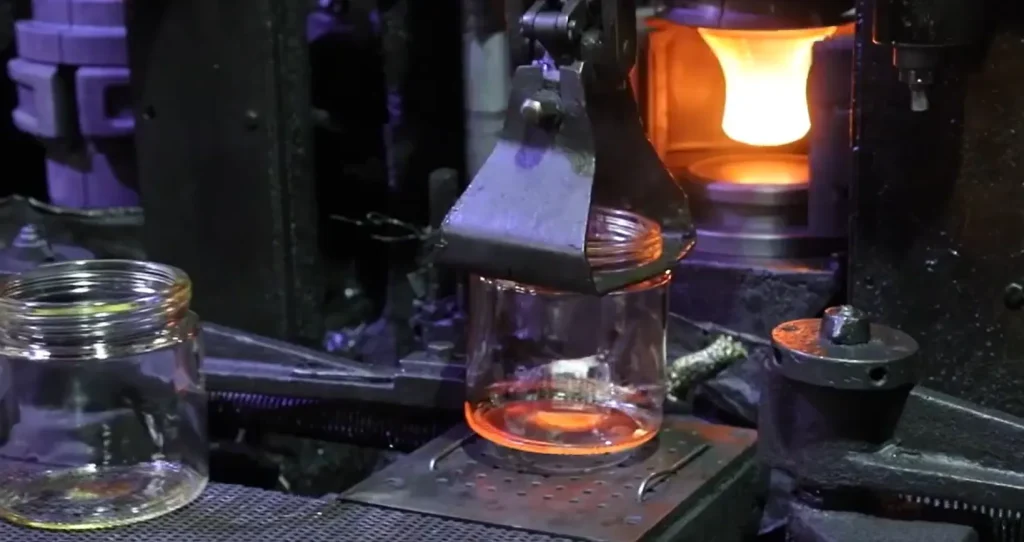

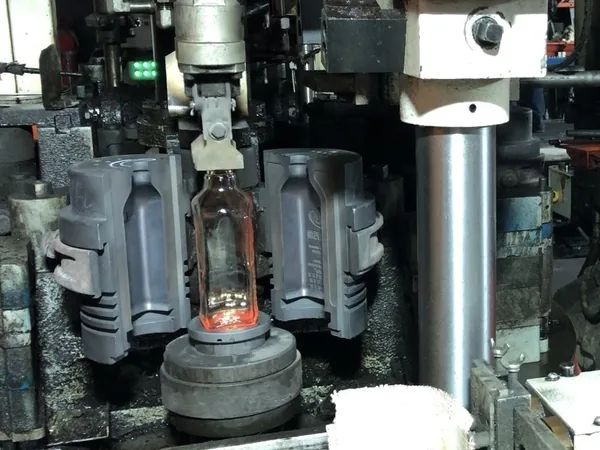

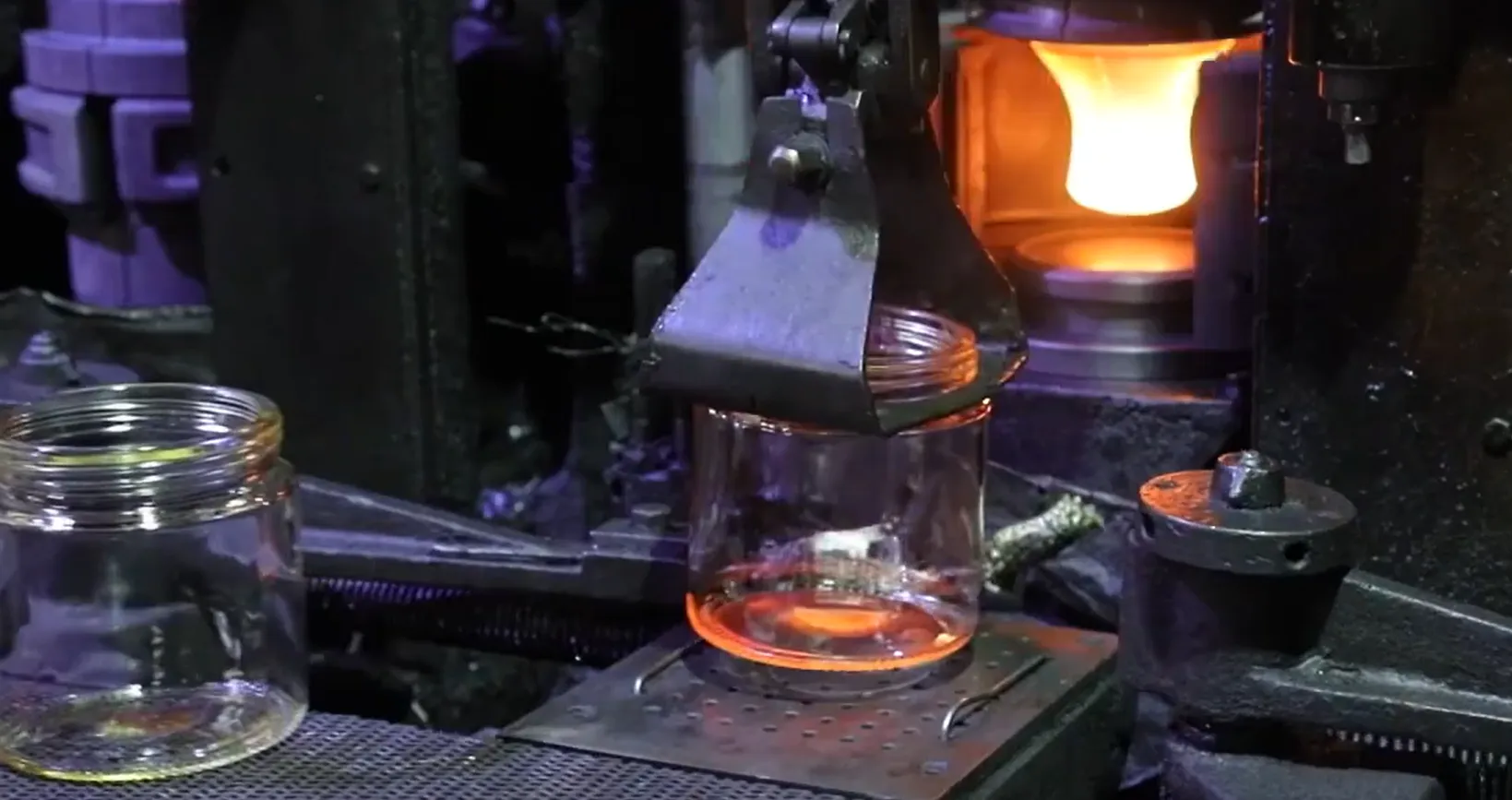

Glass Bottle Factory Video: Manufacturing Process & QC

This short video shows our glass bottle production line in China—from forming (IS machine) and annealing (lehr) to in‑house inspection and export packing. We focus on neck finish consistency, stable glass color, decoration matching, and low breakage delivery for repeat wholesale and custom orders.

- Forming & molding control (IS machine)

- Annealing for strength (lehr)

- In‑house inspection & QC checks

- Export packing to reduce breakage risk

Why Choose MC Glass as Your Glass Bottle Manufacturer

Factory-direct China glass bottle manufacturer with in-house molds, decoration, QC, and export-ready packing.

In‑House Factory & Mold Workshop

In-house mold workshop + IS-machine forming for consistent dimensions and neck finish.

Flexible MOQ & Stable Lead Times

Stable capacity for repeat wholesale orders—clear MOQ, sampling, and production schedule.

Custom Molds & Decoration In One Place

Frosting, screen printing, coating and hot stamping—managed for repeatable branding quality.

Export Packing & Logistics Support

Carton partitions, palletizing and export documentation support—built to reduce breakage risk in shipping.

Glass Bottle Manufacturer FAQs

Factory-direct China glass bottle manufacturer with in-house molds, decoration, QC, and export-ready packing.

We are a factory-direct glass bottle manufacturer in China (not a trading company or marketplace).

In-house production, QC, and export packing

Stable output for repeat wholesale & custom orders

Factory inspection (onsite/video) is available

MOQ depends on bottle type, size, and decoration. We’ll confirm after reviewing your spec.

In-stock standard bottles: MOQ is usually lower

Custom molds / custom shapes: MOQ is higher

Decoration (printing/coating) may affect MOQ

Yes. We can provide samples to help you verify bottle quality and closure compatibility.

Existing samples for standard bottles are available

Pre-production samples for custom projects after mold approval

Shipping cost and sample lead time will be confirmed case-by-case

We support common decoration options for branded glass packaging.

Frosting, silk-screen printing, decals, hot stamping

Spray coating, embossing / debossing (depending on design)

Closure matching + label / packaging solutions

We control neck finish consistency to ensure closure fit and reliable sealing.

Neck finish gauges + in-process dimensional checks

Closure matching based on finish type and tolerance

Sampling inspection before packing and shipment

We use export-ready packing to reduce breakage risk during long-distance shipping.

Strong cartons + dividers / partitions

Palletizing + protective wrapping

Packing verified for export handling

Lead time depends on whether the bottle is in stock or custom-made.

In-stock bottles: typically 10-20 days for production & packing.

Custom bottles (new mold / decoration): typically 30-60 days, including sampling and approval.

Shipping time depends on destination port and booking schedule. We will confirm an accurate delivery timeline after reviewing your bottle spec, quantity, and packaging requirements.

Get a Quote from a Glass Bottle Manufacturer

Share your bottle type, capacity, quantity, decoration needs, and destination port.

We’ll reply with recommended options, MOQ, lead time, and export packing suggestions (usually within 12–24 hours).

Factory-direct • In-house QC • Export-ready packing

Stable lead time • Consistent finish • Low-breakage export packing

Glass Bottle Manufacturer Resources

Practical guides from a factory-direct glass bottle manufacturer in China—MOQ, lead times, quality control, decoration, and export packaging. Built for brand owners, importers, and wholesalers who need stable repeat supply.

Glass Jar Manufacturer Guide: How to Choose the Right Partner & Custom Glass Bottles for Your Brand

For growing food and beverage brands, choosing the right glass jar manufacturer and developing the right custom glass bottles is

What Is the Best Bottle for Storing Oil? (A Complete Guide for Brands in 2025)

When it comes to storing edible oils — from premium extra virgin olive oil and sunflower oil to avocado oil

Custom Glass Spice Jars: Tailored Solutions for Pepper, Salt & Seasoning Brands

In the world of spices, where aroma, freshness, and presentation matter, your packaging speaks volumes about your brand. Whether you’re