Where to buy glass soda lime bottles near me

MC Glass Bottle Company located in Jiangsu Province, China. We have been manufacturing empty glass bottle soda lime material for over 20 years. Soda lime glass bottles are made through mold getting its shape. Custom made mold leads to custom shaped glass bottle. It is easy to get custom glass bottles from glass bottle manufacturer.

Soda lime glass (soda lime silica glass) is the most commonly produced type of glass bottles, making up 90% of all glass manufactured. Having been manufactured for hundreds of years, it is a basic combination of silica, soda, and lime with a variety of useful properties for applications across a variety of industries, including the consumer goods manufacturing, packaging, and scientific sectors. Soda lime glass is ommonly used in windows like float glass. It is often compared and contrasted with its cousin, borosilicate glass.

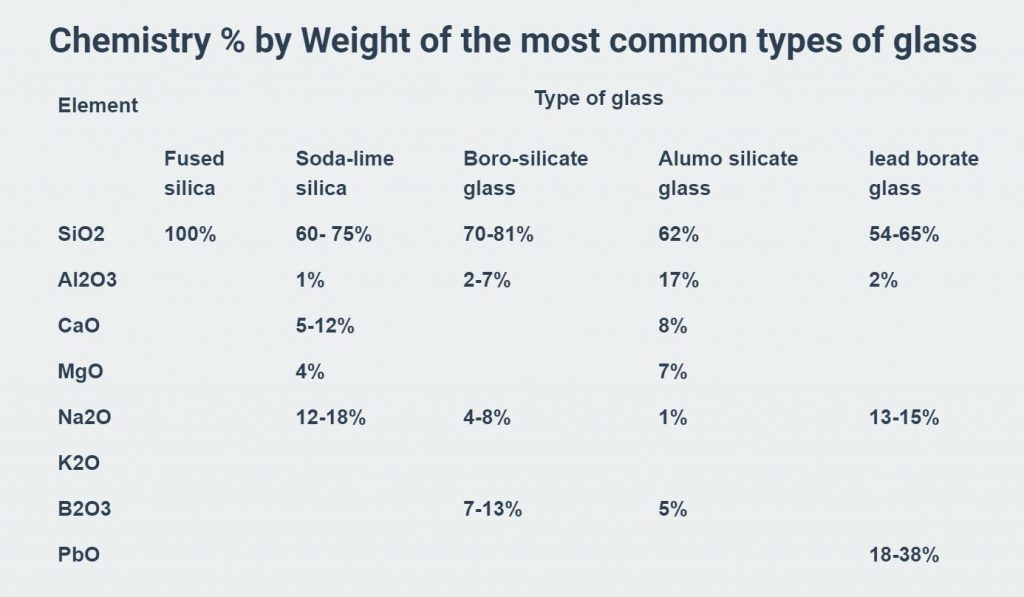

The chemical composition

Soda lime glass is made mostly from three basic components. The first material is silica, or silicon dioxide, which makes up 70% of the finished product. Another 15% is made of soda, or sodium oxide, which lowers the silica’s melting temperature, and lime, also known as calcium oxide, makes up another 9% to act as a stabilizer. The remaining 6% is made up of trace elements.

Soda Lime Glass Properties

Soda lime glass has several properties that make it useful as a glass for general and more specific applications.

It is cheap

Soda lime glass is less expensive than other glass with more specialized properties, such as borosilicate or optical glass.

It is chemically stable

The atoms in soda lime glass have strong atomic bonds and are highly connected, making it difficult for other substances to affect its structure and corrode the glass. This makes it good for use around chemicals, especially if tempered to increase its thermal shock resistance. Soda lime glass is not entirely immune to chemical wear, however, and other more specialized glasses can be more resistant.

It is hard

Soda lime glass is a 6-7 on the Mohs hardness scale, which measures how resistant to abrasion material is. This highest score on this scale is ten and includes materials like diamond. Soda lime glass can also, however, be tempered by heat or chemicals to be made three times stronger. Chemical tempering gives it more mechanical strength, making it harder and more scratch-resistant. Heat strengthening also provides the glass with mechanical strength, with the bonus of making it more resistant to sudden changes in temperature.

It is workable

Thanks to the soda and lime in soda lime glass, it can be softened and resoftened many times without quality loss. This attribute makes it a good material for recycling.

It is vulnerable to thermal shocks

Sudden temperature changes can shatter soda lime glass. This can be reduced by heat tempering, which gives this material added strength.

It is an electrical insulator

Glass does not transmit electricity well, as it has a high specific resistivity and a low dielectric constant. That makes it useful for insulating electrical products.

It transmits visible light

Soda lime glass’s refractive index is roughly 1.5, which means only about 4% of the light that hits it is reflected. The rest passes through, making it an excellent material for applications where light transmission is important.

Soda lime glass bottle and jars applications

Since soda lime glass bottles are cheap, hard, durable, and recyclable, it can be used in many industries. We can find so many glass bottles and glass jars in the supermarket for daily beverage and daily sauce package. Basically, for hot sauce like BBQ sauce, steak sauce, seafood sauce when the inside sauce is in hot temperature need to package into the container, glass bottle is the best material.

Glass sauce bottles

can keep the inside ingredients the favor tasting. Glass sauce jars is more fit for solid sauces since the bottle mouth is bigger than normal. All lids or caps for the containers must have an air-tight seal to protect the integrity of your sauce and meet the food packaging standards in your area. When choosing the size and shape of the bottle, keep in mind it will need to accommodate the kind of label you plan to use.

Milk package glass container

can be keep in low temperature during transportation so glass bottle is assumed to be the best way of premium quality organic milk packages. Not only does it keep the milk tasting crisp, fresh, and unaltered, but consumers also suggest that it feels colder than milk out of a plastic jug or bag. Due to the reduced travel time from farm to shelf, milk in glass bottles is less processed and contains more enzymes, making it easier to digest and even allows some people with dairy intolerance to drink milk from a glass bottle.

Olive oil bottles

Regarding the oil industry, Olive oil can be kept longer than most other edible oils. Although it can get rancid, olive oil is less likely to become rancid than other oils, especially if it is stored properly. The best containers for storage are glass (especially tinted glass), ceramic, porcelain, or non-reactive metals such as stainless steel.

Olive oil will oxidize rapidly if it is not kept in a sealed container. If olive oil is stored in a bottle, always replace the cap on the bottle and keep it tightly sealed. Never put olive oil in a container that does not have a tight cap or some other method of sealing the container. Olive oil should not be stored in plastic containers because the oil may absorb PVC’s from the plastic. So, glass bottle is the best way to container Olive oils.

Beer bottles

are still the dominant form of beer containers sold in retail outlets, occupying the top two slots of IRI Worldwide beer sales data. There are all sorts of thoughts about green, clear and brown glass bottles, with brown being the winner in most hearts and minds.

Defects during production

Part lines: since the mold are two parts, part lines cannot be avoided. High quality bottle’s bottom part line is concentric and barely visible. While some bottles with old molds the part line will be visible and not smooth on the surface. Other defects such as big bubbles, clips on the bottle mouth, defected parting line flashes.

What are the defects of glass bottle and glass jar

Minor defects can be considered: washboard, external dirt, impact mark, prominent mold joint, hard air bubbles (deeply embedded in the glass body), neck ring seam, wavy internal surface, small bubbles (seeds).

Quality tests to be performed on-line on 100% of the bottles

-

- Bottle spacer: creates a space between the bottles on the conveyor belt to avoid contact

- Squeeze test: each bottle is squeezed between two discs to measure cross breaking resistance

- Bore gauger: measures the bore gauge against agreed or established specifications and Tolerances

- Checks detection: a beam of light focuses onto pre-established bottle areas where these defects are statistically located

- Wall thickness: wall thickness measurement by using dielectric properties of glass

- Visual check: bottles are visually inspected by an operator

- Automatic hot end inspections should be carried out before annealing with more advanced techniques like optical devices to detect, blisters, checks, cuts, bird swings and other irregularities by rotating bottles

All faulty bottles are scrapped and crushed into cullet.

Quality tests to be performed in the lab on statistically basis of Capacity, ovality, verticality

-

- Vertical load resistance: measures resistance of bottles during capping or through stacking products on top of each other

- Impact test: resistance to impact, measured generally with Pendulum Impact Tester

- Thermal shock resistance: to determine resistance to thermal shocks of hot fill or pasteurized products (e.g., jam). Testing methods: ASTM C149 or BS EN ISO 7459 at 420 ⁰C

- Coating performance: to determine longevity of of the coating performance – Internal pressure resistance: for bottles containing sparkling wines – Residual strain measurement: measures the annealing stress/residual strain – Testing method: ASTM C 148

- Hydraulic internal pressure: according to ISO 7458

Conclusion

All in all, Soda lime glass bottle are made from a mold, which has two parts. So, the appearance of the bottle surface you can find the part line of the mold. When the mold is dirty or used many times, the bottle surface will be not so good looking. The mold material is alloy. The bottle-made process is complicated so find a qualified supplier can help you to focus on your product itself and the branding of the product.

MC Glass Bottle is your reliable glass bottle manufacture China. Just pass sourcing glass bottle job to us. We can streamline all the bottle making processes, decoration, packaging and logistic to your hand.