MC Glass Bottle Company

act as sustainable way to manufacture glass bottles knowing the maket trends. We are lucky to be in glass bottle industry. We focus on design, development and making glassware for over 20 years with good reputation all over the world.

o a high temperature. Once the stock has been fed into the furnace, temperature inside can be as high as 1675 degrees Fahrenheit. The glass bottle has been proved to be used for food package.

Glass products do not contain heavy metal like migration, leachable lead and cadmium. So, when some business owner and retailor design their products package method they would like to place glass bottle and glass jar as priority.

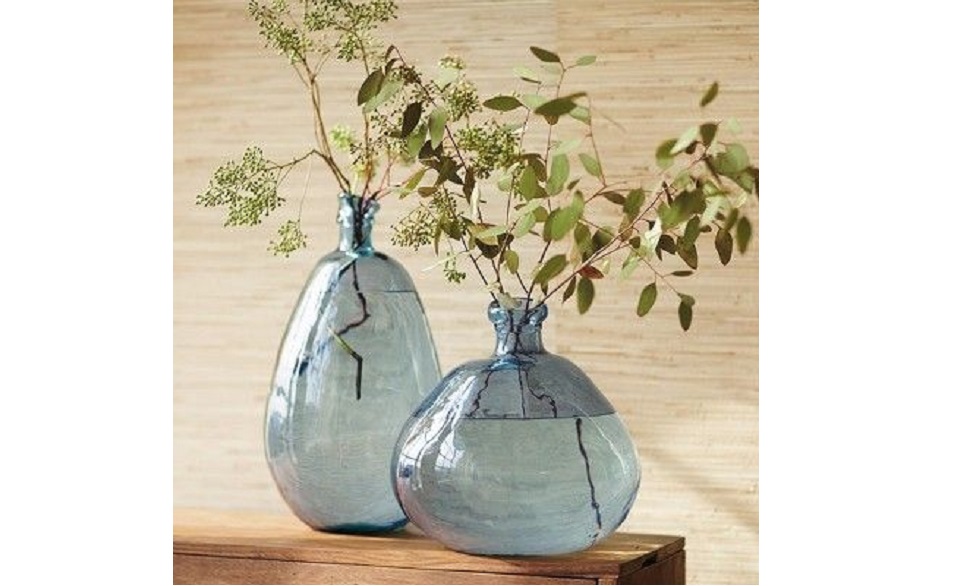

Glass bottle and glass jar can be widely used for all kinds of package, such as Oliver oil, water, liquor, juice, beer, milk, bubble tea, smoothies, coffee, jam, honey, pepper, salt, dry flower, perfume and DIY gifts.

Why Choose glass bottle as the package way

Nowadays, people are more and more care about sustainable development. Compared with plastic, glassware is environmental friendly.

The raw materials of soda lime glass are silicon dioxide (sand) and sodium carbonate, which are natural and not expensive. Small amounts of aluminum oxide, ferric oxide, barium oxide, sulfur trioxide, and magnesia also account for about 5 percent of soda-lime glass. The output of glass container can be recovery and melt then mixed into the raw materials.

Glass products will not release harmful substance when increasing to a high temperature. Once the stock has been fed into the furnace, temperature inside can be as high as 1675 degrees Fahrenheit. The glass bottle has been proved to be used for food package.

Glass products do not contain heavy metal like migration, leachable lead and cadmium. So, when some business owner and retailor design their products package method they would like to place glass bottle and glass jar as priority.

Glass bottle and glass jar can be widely used for all kinds of package, such as Oliver oil, water, liquor, juice, beer, milk, bubble tea, smoothies, coffee, jam, honey, pepper, salt, dry flower, perfume and DIY gifts.

Where to find a Glass Bottle Manufacturer making Custom Glass Bottles

Some clients would like to find a factory as custom glass bottle manufacturer. This is a real cool idea. Let us introduce the processes.

First, client need to provide a technique drawing showing the shape and main dimension including the capacity, height, diameter and top cover. Our factory will draw the mold drawing for approval. If needed, we will first print a 3D model of the bottle before opening real metal mold. Once the mold finished, we will produce physical samples and post them to clients for approval. After approval, our factory will do the mass production.

Normally, the lead time of mold is 3 weeks and the lead time of sample setup is 3 or 4 weeks.

How to Add Custom Logo On Glass Bottles

There is some way for clients to add custom logo directly on the surface of glass package. One way is getting embossed logo on the surface of glass bottles. Our factory can engrave the artwork on the mold. The second way is printing on the surface of glass bottle, no matter the image is one color or multiple colors.

Glass bottle manufacturer call one color printing is silk screen printing. The process is making a film then printing on the surface of bottles. All color printing is more complicated and more expensive than one color printing. We call this process is decal.

First need to make the colorful paper second stick the paper on the surface of bottle then put the sticker bottles into oven. The colorful paper will be transferred on the bottles after high temperature treatment. Some bubble tea stores promote their milk tea with a free printed glass bottle, such as Roasting Water in the United Stated and The Moo Bar in the United Stated. Also, some coffee bar business owner print their flat glass bottle in to matt black and matt white, this is a really cool idea. The customer not only can buy a coffee but also can get a reused glass bottles. In this way, the sale volume will increase.

The third way to add custom logo on the surface of glass bottle is making paper or plastic stickers. Sticker is cheaper and some juice maker has lots of favor incline to use this way. Just forward the artwork, our glass manufacturer will print the sticker and in addition we have machine to labeling the sticker automatically for some clients who would not do themselves.

Conclusion

Where to Find a Glass Bottle Manufacturer Near Me

With over 20 years glass bottle and glass jar making experience, for some style, we always have stocks. So, we can accept small order and provide fast delivery service for some on-stock products orders.

We will list them such as 250ml clear and green Oliver oil glass bottle (square and round), 500ml clear and green Oliver oil glass bottle (square and round), 1000ml clear and green Oliver oil glass bottle (square and round), 300ml/500ml water glass bottle with cork or with stainless steel, 100ml/200ml/250ml/350ml flat coffee glass bottle with metal screwed cap, 100ml/180ml/280ml/500ml/730ml square jam glass jars, 120ml/180ml/280ml/500ml/730ml hexagonal jam glass jars, 8oz/16oz French square glass bottle, 8oz/16oz/32oz clear and amber Boston round glass bottle, 240ml/350ml/500ml/1000ml round glass jars, 100ml/200ml pudding glass jars with cork or with PP lids. Just write email and send inquiry to us.

There are two way to package the glass bottles. One way is putting the bottles onto the pallets and the other way is putting the bottles into export standard cartons or carton plus pallets. Glass product is fragile and do not worry about this.

Based on the experience, by these two ways, glass bottle can be safe during marine transportation and road transportation. We can provide FOB, CIF and door to door service for clients.

There are many kinds of glass bottle and glass jars clients can source from us. The MOQ for a custom made glass bottle is 30,000pcs and for on stock products is one pallet. Glass bottle is not suitable for air transportation since the weigh/volume is very big and the value is small.

Please arrange at least 4 month for receiving mass production glass bottles since mold making need one month, sample making need one month, mass production need one month and shipping by marine need one month.

We welcome client to visit our factory. Free sample, free quote today!