Looking for the perfect custom and branded glass packaging? This guide will walk you through what you need to consider—from product specifications to selecting the professional glass bottle and jar manufacturers, and how to choose an effective solution that enhances your brand and achieves your marketing goals.

In today’s crowded marketplace, packaging is not just a functional container. It is your brand’s first impression. Whether your are lunching a new sauce, cosmetic serum, or dietary supplement, custom packaging sets the tone for quality and trust. How to find the right supplier and solution is essential.

This guide will get you through how to find the ideal custom glass packaging that works for your unique business and product needs.

Know your product and target customs

Your product determines the type of packaging. First, clarify whether the product is a liquid or solid, and assess its sensitivity to light. It’s also important to analyze the needs of the end users—are they highly health-conscious, environmentally minded, or do they prefer a sense of luxury? Are there storage requirements? Does it need to be kept in a refrigerator, used daily, or have special sealing requirements?

For example, amber pill glass bottles are perfect for protecting light-sensitive contents like medications or herbal supplements.

Define your packaging goals

Determine the shape, capacity, and sealing method of the glass bottle. Packaging styles can range from minimalist and modern to classic or luxurious, and should be chosen based on your needs and budget. Do you require engraving, custom colors, or laser printing to enhance brand recognition? Should the glass bottles be recyclable? These packaging goals can influence the glass color and manufacturing process. Custom decorations may include screen printing, decal firing, spraying, labeling, and hot stamping.

Choose the right glass bottle manufacturer

Many sellers are merely distributors and offer limited customization services. Finding a true manufacturer means gaining access to mold production, mold maintenance, lower minimum order quantities, and comprehensive services—from raw material selection and full process control to shipping and customs clearance. Professional manufacturing and extensive experience improve the yield rate, enable personalized product offerings, and ensure high quality.

For true differentiation, partner with a manufacturer who offers mold customization, fully personalized glass packaging, in-house decoration from concept to delivery.

Ask these questions before you commit

When shortlisting suppliers, please ask

-what is the lead time for custom molds

-do you offer samples before production

-are the caps and closures included or separate?

-can you match specific Pantone colors?

-what decoration methods do you offer (labeling, frosting, printing)?

The answers will help you avoid unexpected delays or compromises.

Plan ahead-custom takes time

Here’s a typical timeline

-design+mold:3 to 4 weeks

-sample setup time: 2-3 weeks

-sample approval: 1-2 weeks

-mass production: 2-3 weeks

-decorating/labeling: 1-2 weeks

When you are going to launch a new wellness product in summer, it’s best to start your packaging process in early spring. The total time is 4 to 6 months.

Inspect samples thoroughly

Before placing a large order, it is always necessary to conduct a series of tests. First is a visual inspection to check for small bubbles, scratches, or overly visible mold lines on the glass surface. Then comes drop resistance testing to assess hardness and strength. Tests should also be done to evaluate the durability and adhesion of any printing, the sealing performance of the cap, and the bottle’s resistance to high and low temperatures. If there are special requirements—such as being dishwasher-safe—additional testing is needed to ensure compliance.

Custom glass packaging is not just about looks. It is a strategic decision that affects branding, logistics, and even shelf life. The right supplier can help you go from concept to finished product smoothly.

At MC Glass, we specialize in low MOQ, custom glass bottle and jar manufacturing with full service support for both star-ups and large scale operations. Let us bring your vision to life-beautifully, efficiently and affordably.

Explore bottle types based on use case

Choosing the right bottle is not just about the design. It is about aligning form and function for your specific product. Below are some key categories to consider when customizing the packaging.

Oil glass bottles: For olive oil, essential oils and infused blends, option for bottles with narrow necks to control pouring and minimize waste. Dark amber or green glass is often used to protect sensitive oils from UV exposure.

Custom water bottles: If you are creating a luxury or eco-conscious water brand, think about using clear, minimalist bottles with elegant shapes. These are ideal for reusable product lines or boutique hospitality services. Custom embossing or screen printing can add brand value. Sparking water bottle need to handle carbonation with a metal ropp cap.

Swing-top bottles: Popular in craft beverages like cold brew, kombucha or home-brewed beer, swing-top bottles provide a functional and visually appealing seal. They are also reusable and seen as eco-friendly.

Large Volume Bottles: For bulk sales or commercial ingredients, large volume bottles and jars like 1 litre and above are useful in B2B packaging. Think about handles, wide necks and compatibility with pumps or scoops.

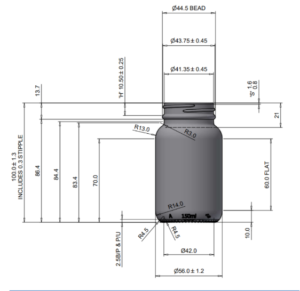

Pill and tablets bottles for supplement packaging:

Sealing and safety

Tamper-evident features: induction seals, shrink bands or safety caps are critical for consumer trust and regulatory compliance.

Child-resistant closures (CRC): required in many markets for safety, especially for pharmaceuticals and certain supplements.

UV protection: use amber or opaque bottles for light-sensitive formulas like herbal tablets.

Moisture protection: tablets are often moisture-sensitive. Descant-lined caps or moisture-resistant coatings may be necessary.

Work with an expert on labeling and branding

Glass bottle and jars may be the foundation while labeling is the storytelling layer that makes people pick it up.

Partner with a manufacturer not only can reply estimated mold cost for a custom design, unit price per bottle, estimated lead time for mold creation and full production, shipping terms and options, but also can offers

Multi-color silk screen printing, custom labels (paper, plastic, metalized), hot-stamping for a premium finish, matte, frosted or glossy coatings.

When designing your label, keep in mind how it looks on shelves and how it is holds up under use especially if refrigerated or used daily.

Sustainability matters more than ever

Modern consumers are conscious of waste. Highlight the sustainable aspects of your packaging by choosing recycled or recyclable glass, biodegradable labels and reusable caps or closures.

You can even offer refills and market your brand as eco-responsible. Custom water and swing-top bottles especially benefit from a reusable-first narrative.

Conclusion

From oil bottles to water jugs, from compact vials to swing-top beverage containers, every design decision communicates value. Your packaging should tell your story before a single word is read.

At MC Glass, we help companies large and small develop smart, stunning packaging that brings their products to life. Whether you are lunching your first item or scaling to global distribution, we are ready to support your vision with full customization, flexible minimums and professional guidance.