A great design of juice glass bottle can be your business competitive advantage

When customers go out for shopping, the first thing they notice about the beverage drinks on the shelf perhaps not the inside ingredients of drinks but the shape and appearance of the bottle. According to Packaging and Purchase Decisions researchers, “Packaging seems to be one of the most important factors in purchase decisions made at the point of sale, where it becomes an essential part of the selling process”.

Today, switching from plastic bottle to glass container with eco-friendly labelling is crucial for sustainable development of our earth. The customers are often most likely to gravitate to the packaging that reflects the quality, ethics and price point they are looking for along with a unique design that stands out from the rest. Some clients would like to pay a little more expensive price to choose a juice bottle manufacturer in glass material than plastic bottle since glass product can be reused and recycled. Packaging design should be a prat of the products’ selling strategy. And the designers should know more customer behavior of concerning about environment friendly and sustainability. Over the last ten years, plastic packaging has taken the hot seat when it comes to waste. Glass packaged juice and products seems as nostalgic and superior quality to the consumer. We can find most organic juice producers intend to package their natural juice in a glass bottle since the flavor will keep the same during low temperature transportation and storage in the fridge when customers buy the juices.

The traditional labelling method is to print label sticker then using machine to attach the sticker onto the surface of glass bottles. In this article we will introduce screen printing methods, which is widely used in glass bottle surface branding.

Why screen printing directly onto the glass bottle is better than labelling stickers

When customers choose paper label stickers, they will prefer round shape glass bottle like Boston round or Voss style bottles. We wrote in the previous blog about the process of glass bottle production and found exactly the pure round shape is very difficult to get out due to mold, material and facility restrictions. That will result in wrinkle, bubble, or tear of paper and plastic label stickers on the surface. When the beverage producers choose a square glass bottle it will not fit to labelling the paper by machine. So, our customers find paperless treatment positively impacts their bottling line efficiency, label durability and design impact.

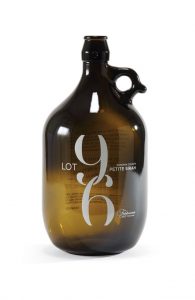

During the direct printing process, like screen printing ceramic or UV based inks are applied and permanently cured directly onto the container. And in this way, customers can design a unique artwork to shine their brands including any color and 360 degree all round bottle printing. Furthermore, the printing process can be tailored to the specific size and shape of your custom bottle whether it is round or square or anything in between.

Consumers are actively changing their purchasing habits to reflect their environmentally friendly values. When using paper sticker on the surface it will quite be difficult to peel the sticker then reuse the bottles. Glass packaging that is free of single-use labelling is sure to stand out to eco-conscious buyers. Screen printing glass packaging is a very eco-friendly choice that fits recycle, reuse, and reduce. Glass bottle packaging can be recycled and reused multiple times which in turn ends up reducing its environmental impact.

Many businesses including milk delivery services, juice bar, bubble tea bar and craft breweries make reusing their glass bottles and jugs a part of their business model. For example, our client The Moo Bar in United States of America, they can sell 6,000pcs bubble tea one month with mason glass jar printing with different designed logo attracting the customers to reuse the glass bottle in their home. Also, some funs intend to collect a series of designed jar and buy more and more bubble tea, milk tea and smoothies. They are successfully expanded another bubble tea bar in Seattle very poplar nowadays. Another example, when milk gets delivered to customers, the milkman picks up the empty glass milk bottles manufacturer from the previous delivery. The glass bottles are then brought back and are sterilized using specialized glass bottle washing equipment. Finally, the bottles are refilled with milk and are delivered continuously.

What is the Process of Screening Printing on a Glass Bottle

Age of Screen Printing

Screen printing’s original roots go back to Egyptian times with stenciling and then later in China (900 A.D.) when they first forced ink through silk fabric to create images. It was then that ancient artists first stretched silk fabric across a frame and poured hot beeswax into it. Although, it wasn’t until the 1880’s that screen printing took off as a commercial process for decorating fabric.

Screen printing was largely introduced to Western Europe from Asia sometime in the late 18th century but did not gain large acceptance or use in Europe until silk mesh was more available for trade from the east and a profitable outlet for the medium discovered.

Screen printing on bottles, also know as applied color labeling (ACL), is delicate process that we have been perfecting for over 10 years. Utilizing the bottle as a canvas, we can work with standard colors and precious metals to create a label that is permanently fused to the glass.

Process of Screen Printing

The first step is to design the logo

Before you begin the actual design of your label, make sure you can send the right signals to your target audience. The label will help consumers better understand your products. Make sure your brand’s image is simple, prominent and clear. Keeping your brand’s name front and center-in a font that is easy to read, which will make the product much more desirable. Choose an attractive image since an image is worth a thousand words. Tell a story for your product than any copy you include. The bottle graphics and imagery can play an enormous role in a consumer picking your bottle up and deciding to buy it.

That is an example-Appeal to consumers’ senses and choose an image that evokes a sense of time or place that your target audience will relate to.

Furthermore, you need to know trend like frosted surface, which color can reflect your brand and what your brand stands for. While not the most exciting part of a label’s design, industry standards like product name, ABV, weight, capacity, government warning and bar code will need to be included, so think about where they will appear without getting in the way of message.

The second step is to make a film

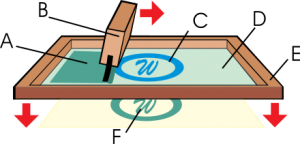

The third step is to transfer the film image to a nylon mash

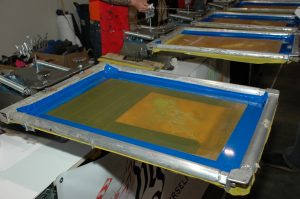

Next, the screen and frame are lined with a tape to prevent ink from reaching the edge of the screen and the frame. The type of tape used in for this purpose often depends upon the ink that is to be printed onto the substrate. More aggressive tapes are generally used for UV and water-based inks due to the inks’ lower viscosities and greater tendency to creep underneath tape. With the ink forming a design, it is applied to the substrate of or the surface of the glass container to be decorated. Three are almost no limits to the types of glass containers that can be screen printed. However, screen printing works best on hard and flat surfaces. The full Pantone color is available in screen printing, including bespoke colors. There are also specialty inks that mimic the metallic look of a gold foil, and coated inks that add a high glossy shine to any color or matt colors. Each color is applied one at a time, using a new screen for each color.

Screen printing on a glass container creates one of the most unique looks in the market, especially on clear glass. Transparent inks create the effect of light-filled color on a clear background that can elevate the shelf appeal of many products. Designed artwork with silk screen on glass are exceptionally durable because the ink adheres directly to the glass bottles.

Next, the screen and frame are lined with a tape to prevent ink from reaching the edge of the screen and the frame.

The type of tape used in for this purpose often depends upon the ink that is to be printed onto the substrate.

The last step is to put the glass bottle in the furnace.

Because of the high temperature the ink adheres directly onto the surface of glass container and the color is permanently. Then the front-line workers will clean the glass bottle surface, do the final inspection, and put them into the cartons.

MC Glass Bottle Company fulfill screen printing for glass bottles

No matter the glass bottle is big or small, your reliable glass bottle manufacturer can fulfill screen printing process in high quality and attractive appearance. We will help the client to shine their brands and sell more and more in the markets.

Thanks for the various ink available, the brand new and unique ink including glitter/shimmer, gloss and metallic. Our company can fulfill the printing logo in the following three effects. Glitter or shimmer ink is when metallic flakes become an additive in the ink base to create this sparkle effect. Usually available in gold or silver but can be mixed to make most colors. Gloss ink is when a clear base laid over previously printed inks to create a shiny finish. Metallic ink is similar to glitter, but smaller particles suspended in the ink. A glue is printed onto the fabric, then nano-scale fibers applied on it. This is often purchased already made.

To print multiple copies of the screen design on garments in an efficient manner, our company now use more sophisticated printing press. These presses normally come in three types, manual, semi-automatic and fully automatic. We use semi-automatic to make the output of printing in good appearance and in a more efficient way.